|

TOPTITECH

|

SS316L Porous Metal Solid Cylinder Filter Without Connector

| Price: | 25.0 USD |

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Specifications:

Material: SS316L powder

Pore size: 1um

Length: 125mm

Diameter: 10mm

Technique: Sintering

TOPTITECH's SS316L Porous Metal Solid Cylinder Filter Without Connector is contrived from premium stainless steel 316L using advanced powder metallurgy techniques, this filter distinguishes itself from traditional filter cartridges with its solid cylindrical structure that no connectors. Offering a filtration precision of 1 micron, this filter epitomizes unparalleled efficiency and precision in capturing minute particles with exceptional accuracy.

This innovative filter's design not only ensures a seamless fit into systems necessitating the removal of ultrafine particles but also guarantees robustness and resilience against challenging environments. Tailored for demanding applications across industries such as pharmaceuticals, food and beverage, and chemical processing, this filter promises unmatched filtration performance for critical operations where precision is paramount.

Specifications

Material: SS316L powder

Pore size: 1um

Length: 125mm

Diameter: 10mm

Technique: Sintering

Features

Micron Filtration Precision: Boasting a filtration accuracy of less than 1 micron, this filter excels in capturing even the smallest particles with exceptional precision.

Premium Stainless Steel Construction: Crafted from top-quality stainless steel 316L, this filter guarantees durability, corrosion resistance, and a long service life in demanding industrial settings.

Innovative Solid Cylinder Design: Its unique structure, free from connectors, enhances both robustness and ease of installation, ensuring a seamless filtration process.

Enhanced Filtration Efficiency: The advanced design of this filter maximizes filtration efficiency, delivering superior performance in critical applications.

Reliable Performance: Engineered for consistent and reliable operation, this filter withstands challenging conditions while maintaining optimal filtration performance.

Precision Filtration: Tailored for applications requiring precise filtration, this filter consistently provides accurate and dependable results.

Low Maintenance Requirements: This filter's robust design and high-quality materials reduce maintenance needs, saving time and resources in the long run.

Long Service Life: With its durable construction and resistance to corrosion, this filter offers an extended service life, providing ongoing reliability and cost-effectiveness.

Applications

Gas Sparging in Chemical Processing: Utilized as a gas sparger, this filter facilitates the efficient introduction of gas into liquids for various chemical processes, ensuring optimal reaction conditions and enhanced productivity.

Aeration Systems in Water Treatment: Integrated into aeration systems, this filter aids in the oxygenation of water, promoting effective treatment processes in wastewater treatment plants and aquaculture facilities.

Gasification in Petrochemical Industries: Employed for gasification purposes, this filter assists in converting liquid fuels or feedstocks into gaseous products, supporting operations in the petrochemical sector.

Air Purge Applications in Pharmaceutical Manufacturing: Applied for air purge processes, this filter helps maintain clean and sterile environments in pharmaceutical manufacturing, safeguarding product quality and compliance with industry standards.

Gas Dispersion in Food and Beverage Processing: Used for gas dispersion, this filter ensures uniform distribution of gas in food and beverage processing, enhancing product quality and process efficiency.

Bioreactor Aeration in Biotechnology: Integrated into bioreactor systems, this filter aids in providing essential aeration for microbial growth and bioprocesses in biotechnological applications, optimizing yields and product quality.

Ventilation Systems in HVAC: Incorporated into ventilation systems, this filter contributes to air purification and gas exchange in heating, ventilation, and air conditioning (HVAC) systems, maintaining indoor air quality and comfort.

Experience

The solid stainless steel powder sintered filter and the hollow stainless steel powder sintered filter tube differ in structure and application:

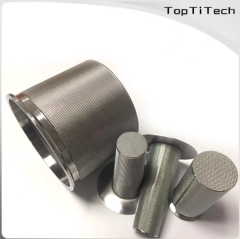

Solid Stainless Steel Powder Sintered Filter:

Structure: The entire filter is made of a uniform solid stainless steel powder-sintered material without any hollow parts.

Characteristics: Due to its solid structure, it is more durable and suitable for environments requiring high filtration precision and long-term stable operation.

Applications: Commonly used for efficient filtration of particles, impurities, etc., in areas such as water treatment, food processing, and more.

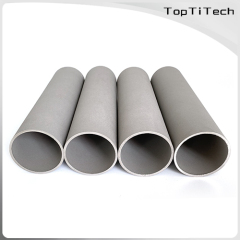

Hollow Stainless Steel Powder Sintered Filter Tube:

Structure: The filter tube is hollow, made of stainless steel powder-sintered material with gaps in the middle for the passage of liquids or gas.

Characteristics: Compared to solid filter cartridges, hollow filter tubes have a larger filtration area and lower resistance, making them suitable for high-flow filtration requirements.

Applications: Widely used in industries such as chemical, petroleum, and pharmaceuticals for filtering out fine particles and impurities from liquids or gas.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the designated place of the customer without damage.

Contact Us

TEL: +8619992203758

Company: TOPTITECH _ BAOJI YINGGAOCO., LTD

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China