|

TOPTITECH

|

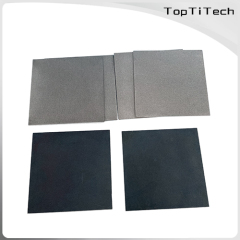

Porous titanium round plate Diffusion Layer Hydrogen Electrode

| Price: | 10.0 USD |

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

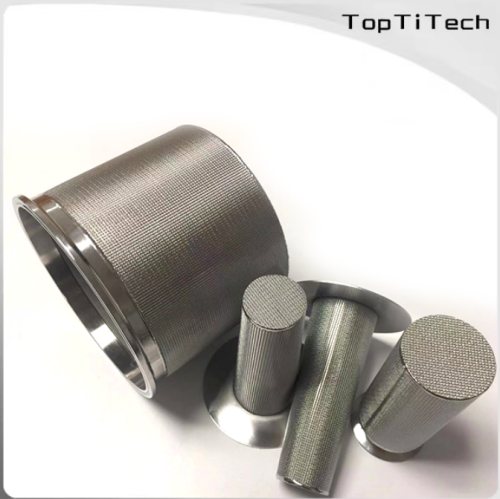

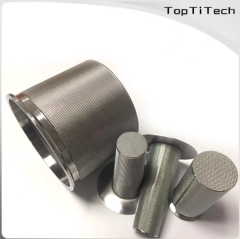

Material: SS 316L

Size:φ100*500mm

Inner perforated mesh: 8 mesh

Outer wire mesh: 50 mesh

Technique: Welding

Product Introduction

TOPTITECH's SS 316L Perforated Mesh Wire Mesh Combination Filter Barrel combines two layers of stainless steel mesh, featuring an outer layer of stainless steel wire mesh and an inner layer of stainless steel perforated mesh. Crafted from premium SS316L material, this filter barrel offers exceptional durability, corrosion resistance, and heat tolerance.

The inner layer of perforated mesh provides structural support, ensuring the longevity and integrity of the filter barrel. Its precise perforations allow for efficient fluid flow while effectively trapping solid particles and impurities. The outer layer of wire mesh acts as the primary filtration medium, providing fine filtration capabilities and preventing larger contaminants from entering the system.

Specifications

Material: SS 316L

Size:φ100*500mm

Inner perforated mesh: 8 mesh

Outer wire mesh: 50 mesh

Technique: Welding

Features

Dual-layer Filtration: Benefit from the synergistic effect of two layers of stainless steel mesh. The inner perforated mesh provides structural support, while the outer wire mesh ensures effective filtration, resulting in enhanced filtration efficiency.

Premium SS316L Material: Enjoy the superior corrosion resistance, durability, and high-temperature tolerance offered by the SS316L stainless steel construction. This ensures long-lasting performance and reliability in demanding filtration applications.

Optimal Filtration Efficiency: The precise perforations of the inner layer allow for efficient fluid flow while effectively trapping solid particles and impurities. The outer wire mesh acts as a robust filtration medium, preventing larger contaminants from entering the system.

Extended Service Life: The combination of sturdy wire mesh and perforated mesh provides structural integrity, resulting in a longer service life compared to single-layer filters. This reduces downtime and maintenance costs, enhancing overall operational efficiency.

Reliable Performance: Count on the SS 316L Perforated Mesh Wire Mesh Combination Filter Barrel to consistently deliver reliable filtration results. It meets industry standards and ensures the purity and quality of your processes.

Easy Installation and Maintenance: The open-ended design of the filter barrel allows for easy installation and maintenance. Its robust construction simplifies cleaning and replacement procedures, saving valuable time and effort.

Differences between stainless steel perforated mesh and stainless steel wire mesh

Stainless steel perforated mesh and stainless steel wire mesh are two common types of stainless steel grid materials with distinct structural and functional differences. Here are the key differences between them:

Structure: Stainless steel perforated mesh is created by punching holes in stainless steel sheets, resulting in a mesh structure with regular and precise openings. On the other hand, stainless steel wire mesh is woven by interlacing stainless steel wires, similar to the process of fabric weaving.

Filtration Capability: Due to its unique structure, stainless steel perforated mesh provides precise hole sizes and porosity, enabling fine filtration. It effectively blocks particles and impurities while maintaining high flow rates. Stainless steel wire mesh has a relatively lower filtration capability and is typically used for general filtration needs.

Strength and Durability: Stainless steel perforated mesh offers high strength and rigidity, providing excellent structural support. It remains stable under pressure and loads, ensuring a longer lifespan. Stainless steel wire mesh is more flexible and adaptable, suitable for applications that require bending and shape adaptability.

Application Areas: Stainless steel perforated mesh is commonly used in liquid filtration, gas filtration, sound insulation, and thermal insulation applications, especially in situations that require high-precision filtration. Stainless steel wire mesh finds wide applications in areas such as sieve screens, filters, retaining walls, and decorative mesh, catering to general screening and filtration tasks.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the designated place of the customer without damage.

Contact Us

+8619992203758

Company: TOPTITECH _ BAOJI YINGGAOCO., LTD

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China