|

TOPTITECH

|

Porous Stainless Steel Flame Arrestors

| Price: | 10.0 USD |

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

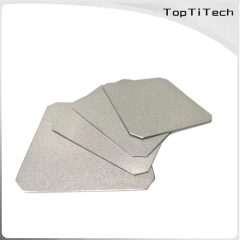

Filtration precision:0.2um-100um(5um, 10um, 20um, 40um and 100um are popular choice)

Material: SS 316L, SS304

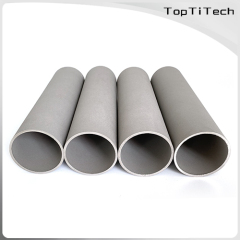

Diameter: 4-500mm

Product Introduction

Stainless steel porous flame arrestors are commonly used in a wide range of industries to prevent the propagation of flames and explosions in systems that handle flammable gas or fluids. They are highly effective at trapping or extinguishing flames while allowing for the efficient flow of gas or fluids. Stainless steel is a popular material due to its high strength, corrosion resistance, and ability to withstand high temperatures.

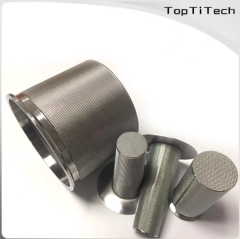

The stainless steel porous filter element is the key component of the flame arrestor and is designed to trap or extinguish any flames that may be present in a gas or vapor stream while allowing gas or fluids to flow through.

When a gas or vapor mixture passes through the porous filter, any flames present will be cooled and extinguished due to the heat dissipation and surface area of the filter. This prevents the flame from propagating further down the pipeline or vessel and causing a fire or explosion. The porous filter also provides a large surface area for vapor or gas to pass through, allowing for efficient flow and minimal pressure drop.

Stainless steel is a popular material for flame arrestor filters due to its high strength, corrosion resistance, and ability to withstand high temperatures.

Parameters

Place of origin: Baoji, China

Brand: TOPTITECH

Filtration precision:0.2um-100um(5um, 10um, 20um, 40um and 100um are popular choice)

Material: SS 316L, SS304

Working temperature:≤ 600℃

Length: 50-1000mm(More than 1000mm can be welded)

Diameter: 4-500mm

Wall Thickness: 1-5mm

Features

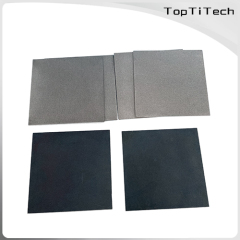

High temperature resistance: Stainless steel filter flame arrestors are designed to withstand high temperatures, making them suitable for use in applications where high-temperature gas or fluids are present.

Corrosion resistance: Stainless steel is highly resistant to corrosion, making it ideal for use in harsh environments where corrosive gas or fluids are present.

Precise gas flow control: Porous stainless steel filters provide precise control over gas flow, allowing for efficient system operation.

Mechanical quenching of flame fronts: The porous filter element of the flame arrestor mechanically quenches flame fronts, preventing them from propagating further down the pipeline or vessel.

High strength and durability: Stainless steel is a strong and durable material that can withstand the high pressures and stresses present in many industrial applications.

Low pressure drop: The porous filter element of the flame arrestor has a low pressure drop, which minimizes the impact on the system´s performance.

Easy maintenance and inspection: Stainless steel filter flame arrestors are easy to clean and inspect, allowing for regular maintenance to ensure optimal performance.

Applications

Venting for explosion proof enclosures

Pressure equalization for combustible gas pressure regulators

Flashback prevention for welding torches

Flame arrestors for industrial cutting torches

Gas detectors for mining operations

storage tanks, pipelines, and processing equipment where flammable gas or liquids are present

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer's designated place without damage.

Contact Us

+8619992203758

Company: TOPTITECH _ BAOJI YINGGAOCO., LTD

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China